|

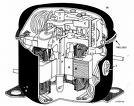

Refrigeration compressors! Compressors – Are the “hearts” of the refrigeration system. The air conditioner, refrigerator, cooler, chiller, and freezer will need one to get up and running. It pumps refrigerant gas into the system. Just like a human heart, it circulates the refrigerant gas in order to perform the refrigeration cycle repeatedly.  Inside the steel casing, you will find an electric motor,a cylinder, piston, crankshaft, connecting rod, intake and exhaust valves, and a ceramic terminal block. About a pint of capilla oil can be found inside. Larger unit needs more oil, please consult manufacturer’s instruction as to how much oil must be added.  As much as possible, do not turn the compressor upside down, because the oil inside will wet the electrical windings. Just keep it in its upright position until it is fastened to the chassis. The suction copper tube has a larger diameter, and the discharge tube has a smaller one.

This is the standard of distinguishing the two and should be observed carefully specially if you are the one doing a replacement. Some compressors have two extra copper tubes on the lower side, they are the oil-cooling tubes. The heat of the capilla oil is transferred to the cooler refrigerant gas and is released into the atmosphere via the condenser coil.  Keep the rubber plugs “in” the copper tubing. Do not remove them because the atmospheric air will come charging in, and they are detrimental to the internal parts. The unit is being vacuum until it is ready for assembly. You will find a three-terminal pin on a Bakelite. They are the drive stator connecting pins. The one on the top is the

“common” terminal, and one on the left is the “start” terminal, and the one on the right is the “run” terminal. There are three rubber bushings, or grommets, that need to be installed on the base plate. They are the vibration dumpers, and absorb the vibrations produced. Without it the unit will be very noisy. Always give enough breathing room, don’t place your unit against a wall, or anything that will obstruct the air flow. The compressor is a very hard working machine, during operation, it is very hot and the heat must be dissipated into the atmosphere. The specifications can be found on a label by its side. You will find the brand, the model number, the LRA, or the “lock rotor current”, but it is a good practice too to find out its “running current”, the type of refrigerant gas used, and the horse power rating. The following is a “running current” and the “lock rotor current” list for a single phase, full load air conditioner motor.

Return from Compressors to Home Page Air-conditioning-and-refrigeration.com (the website) strives to maintain the highest standards of decency, fairness and integrity in all our operations. Likewise, we are dedicated to protecting our customers', consumers' and online visitors' privacy on ourwebsite.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||